We strongly encourage users to use Package manager for sharing their code on Libstock website, because it boosts your efficiency and leaves the end user with no room for error. [more info]

Rating:

Author: MIKROE

Last Updated: 2019-08-05

Package Version: 1.0.0.0

mikroSDK Library: 1.0.0.0

Category: Motion

Downloaded: 2665 times

Not followed.

License: MIT license

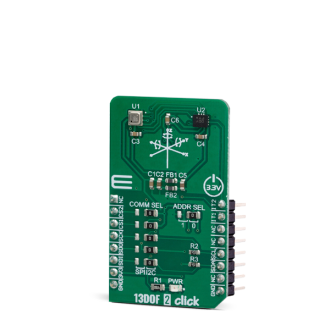

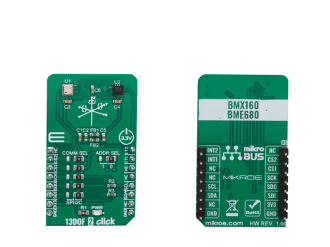

13DOF 2 click is an advanced 13-axis motion tracking Click board, which utilizes two different sensor ICs onboard: BME680, voc, humidity, pressure and temperature sensor and BMX160, a 9-axis sensor consisting of a 3-axis, low-g accelerometer, a low power 3-axis gyroscope and a 3-axis geomagnetic sensor.

Do you want to subscribe in order to receive notifications regarding "13DOF 2 click" changes.

Do you want to unsubscribe in order to stop receiving notifications regarding "13DOF 2 click" changes.

Do you want to report abuse regarding "13DOF 2 click".

Library Description

The library contains basic functions for starting both sensors and reading data that the sensors measure.

Key functions:

void c13dof2_bmx160_getAxis(uint8_t sensor, T_C13DOF2_BMX160_AXIS *sAxis) - Reads Axis data from the BMX160 sensor (Accel, Gyro, Magnetic).uint16_t c13dof2_bmx160_getStepCounter() - Read Step counter.float c13dof2_bme680_getAmbientData(uint8_t dataIn) - Reads Ambient data from BME680 sensor (Temperature, Pressure and Humidity).Examples description

The application is composed of three sections :

void applicationTask()

{

/* BMX160 */

c13dof2_bmx160_getAxis(_C13DOF2_BMX160_DATA_ACCEL, &Accel);

c13dof2_bmx160_getAxis(_C13DOF2_BMX160_DATA_GYRO, &Gyro);

c13dof2_bmx160_getAxis(_C13DOF2_BMX160_DATA_MAGNET, &Magnet);

temperature_bmx160 = c13dof2_bmx160_internalTemperature();

step_counter = c13dof2_bmx160_getStepCounter();

c13dof2_bmx160_getInterruptStatus(&status);

/* BME680 */

temperature = c13dof2_bme680_getAmbientData(_C13DOF2_BME680_DATA_TEMPERATURE);

pressure = c13dof2_bme680_getAmbientData(_C13DOF2_BME680_DATA_PRESSURE);

humidity = c13dof2_bme680_getAmbientData(_C13DOF2_BME680_DATA_HUMIDITY);

gas = c13dof2_bme680_getGasResistance();

mikrobus_logWrite( "-------------------------------------------------------" , _LOG_LINE );

mikrobus_logWrite( "------ BMX160 DATA ------", _LOG_LINE );

_displayData_BMX160();

mikrobus_logWrite( "------ BME680 DATA ------", _LOG_LINE );

_displayData_BME680();

mikrobus_logWrite( " ", _LOG_LINE );

Delay_ms( 1000 );

}

Additional Functions :

Other mikroE Libraries used in the example:

Additional notes and informations

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.