We strongly encourage users to use Package manager for sharing their code on Libstock website, because it boosts your efficiency and leaves the end user with no room for error. [more info]

Rating:

Author: MIKROE

Last Updated: 2016-02-18

Package Version: 1.0.0.0

Example: 1.0.0.0

Category: USB

Downloaded: 3562 times

Followed by: 1 user

License: MIT license

This is demonstration project how FTDI click can be used to control slave microcontroller via I2C.

Lower nibble of slave address is masked which enables the master to address slave using eight different addresses.

Currently four addresses are implemented for different functionality.

Do you want to subscribe in order to receive notifications regarding "FTDI click - Example" changes.

Do you want to unsubscribe in order to stop receiving notifications regarding "FTDI click - Example" changes.

Do you want to report abuse regarding "FTDI click - Example".

| DOWNLOAD LINK | RELATED COMPILER | CONTAINS |

|---|---|---|

| 1365689349_ftdi_click___exa_other_other.rar [1.26MB] | Other Compiler |

|

| 1365689619_ftdi_click___exa_mikrobasic_pic.rar [33.38KB] | mikroBasic PRO for PIC |

|

| 1365689640_ftdi_click___exa_mikroc_pic.rar [32.97KB] | mikroC PRO for PIC |

|

| 1365689657_ftdi_click___exa_mikropascal_pic.rar [33.43KB] | mikroPascal PRO for PIC |

|

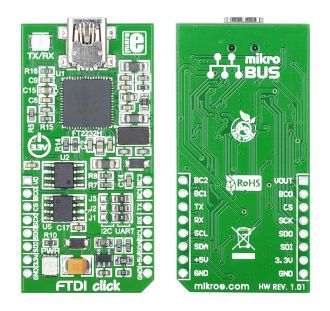

Front and back view of FTDI Click Board designed in mikroBUS form factor.

View full imageFTDI click is accessory board in mikroBus form factor which enables you to connect, PC and MCU applications using preferred communication protocol (I2C, SPI, UART).

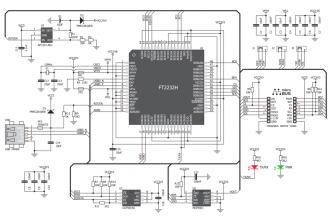

It features FT2232H chip - dual high speed USB 2.0 to UART/I2C/SPI serial interface converter.

In this example project PC Application is communicating with MCU connected on EasyPIC v7 development system via I2C.

PC is master and MCU is receiving control instructions in I2C(MSSP) interrupt routine.

Currently only few functions are implemented, but they can be easily expanded on more functions.

- Send first/second line of typed text to MCU.

(received text is displayed on LCD located on EasyPIC v7 development system)

- Send command to MCU, which then plays the song on Buzzer.

- Control individual pins on PORTD of microcontroller.

Microcontroller is controller via Windows application which is provided in this package.

(Application is written in Visual Studio 2010 Express and LibMPSSE-I2C dll).

http://www.ftdichip.com/Support/SoftwareExamples/MPSSE/LibMPSSE-I2C.htm

Example is written for :

- EasyPIC v7 - PIC18F45K22