We strongly encourage users to use Package manager for sharing their code on Libstock website, because it boosts your efficiency and leaves the end user with no room for error. [more info]

Rating:

Author: MIKROE

Last Updated: 2019-01-28

Package Version: 1.0.0.1

mikroSDK Library: 1.0.0.0

Category: Brushed

Downloaded: 5949 times

Not followed.

License: MIT license

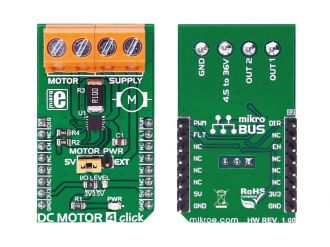

DC MOTOR 4 click is capable of driving motors between 4.5V and 36V. It carries the MAX14870 motor driver from Maxim Integrated. The click is designed to run on either 3.3V or 5V power supply. DC MOTOR 4 click communicates with the target MCU over the following pins on the mikroBUSâ„¢ line: PWM, AN, CS, and INT.

Do you want to subscribe in order to receive notifications regarding "DC Motor 4 click" changes.

Do you want to unsubscribe in order to stop receiving notifications regarding "DC Motor 4 click" changes.

Do you want to report abuse regarding "DC Motor 4 click".

Library Description

The library covers all the necessary functions to control DC Motor 4 Click board.

DC Motor 4 Click communicates with the target board via PWM module.

This library contains drivers for movement direction-control ( forward or reverse),

enable/disable the motor,function for diagnostics and PWM function: initialization, for sets duty ratio, starts and stops PWM module.

Key functions:

void dcmotor4_setForwardMovement() - Set the direction-control of the motor forward movement function.void dcmotor4_setReverseMovement() - Select left direction, fast decay function.void dcmotor4_enable() - Enable the motor function.Examples description

The application is composed of the three sections :

void applicationTask()

{

mikrobus_logWrite( " Forward Movement ", _LOG_LINE );

dcmotor4_setForwardMovement();

dcmotor4_enable();

Delay_1sec();

for ( dutyCycle = 500; dutyCycle < 3000; dutyCycle += 250 )

{

dcmotor4_pwmSetDuty( dutyCycle );

mikrobus_logWrite( " >", _LOG_TEXT );

Delay_1sec();

}

dcmotor4_disable();

mikrobus_logWrite( "", _LOG_LINE );

Delay_1sec();

mikrobus_logWrite( "---------------------", _LOG_LINE );

mikrobus_logWrite( " Reverse Movement ", _LOG_LINE );

dcmotor4_setReverseMovement();

dcmotor4_enable();

Delay_1sec();

for ( dutyCycle = 500; dutyCycle < 3000; dutyCycle += 250 )

{

dcmotor4_pwmSetDuty( dutyCycle );

mikrobus_logWrite( " <", _LOG_TEXT );

Delay_1sec();

}

mikrobus_logWrite( "", _LOG_LINE );

mikrobus_logWrite( "---------------------", _LOG_LINE );

dcmotor4_disable();

Delay_1sec();

}

Additional Functions :

uint32_t dcmotor4_pwmInit(uint16_t freq)- Initializes the Timer module in PWM mode.void dcmotor4_pwmSetDuty(uint16_t duty)- The function changes PWM duty ratio.void dcmotor4_pwmStart()- Starts appropriate PWM module.void dcmotor4_pwmStop()- Stops appropriate PWM module.Other mikroE Libraries used in the example:

Additional notes and information

Depending on the development board you are using, you may need USB UART click, USB UART 2 click or RS232 click to connect to your PC, for development systems with no UART to USB interface available on the board. The terminal available in all MikroElektronika compilers, or any other terminal application of your choice, can be used to read the message.